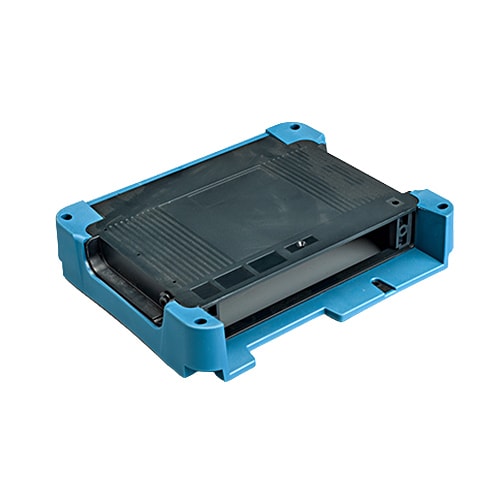

What Is Injection Molding?

Injection molding is a high-efficiency manufacturing process used to create plastic parts by injecting molten thermoplastic into precision-engineered metal molds. After cooling, the material solidifies into consistent, dimensionally accurate shapes. This method is ideal for producing large volumes of complex plastic components at low unit costs, offering excellent repeatability and tight tolerances.

Rapid-Model offers injection molding solutions that combine engineering precision with cost efficiency. Our high-quality plastic parts come with flexible pricing and faster turnaround times. Our team supports complex geometries, tight tolerances, and high-volume production—making us a smart choice for companies seeking mid-tier pricing with high-end performance.

Learn More About Us