What is prototype?

A prototype is an early sample, model, or release of a product built to test a concept or process,it is the first step to verify the feasibility of the product, It is the most direct and effective way to find out the defects, shortcomings and disadvantages of the designed product, so as to correct the defects. Targeted improvements are made until no deficiencies can be found in individual prototypes. At this point, it is usually necessary to conduct a small-scale trial production to find out the shortcomings in the batch for improvement. Designed products generally cannot be perfect or even usable. Once produced directly, all defects will be scrapped, which is a great waste of manpower, material resources and time. Prototypes generally only have a small number of samples, with a short production cycle, low consumption of manpower and material resources, and very high cost. Quickly find out the shortcomings of product design and improve them, providing sufficient basis for product finalization and mass production.

According to production method:

According to the production method, prototypes can be divided into manual prototypes and CNC prototypes:

(1) Manual prototype: The main workload is completed by hand.

(2) CNC prototype: The main workload is completed with CNC machine tools, and depending on the equipment used, it can be divided into laser rapid prototyping and machining center (CNC) prototype.

A: SLA prototypes: mainly prototypes produced using laser rapid prototyping technology.

B: CNC prototypes: mainly prototypes produced by machining centers.

Compared with CNC prototypes, RP prototypes have their own advantages:

The advantage of laser RP prototypes is mainly reflected in its rapidity, but it is mainly formed through accumulation technology. Therefore, laser RP prototypes are generally relatively rough and have certain requirements for the thickness of the product. For example, if the thickness is too thin, it cannot be produced.

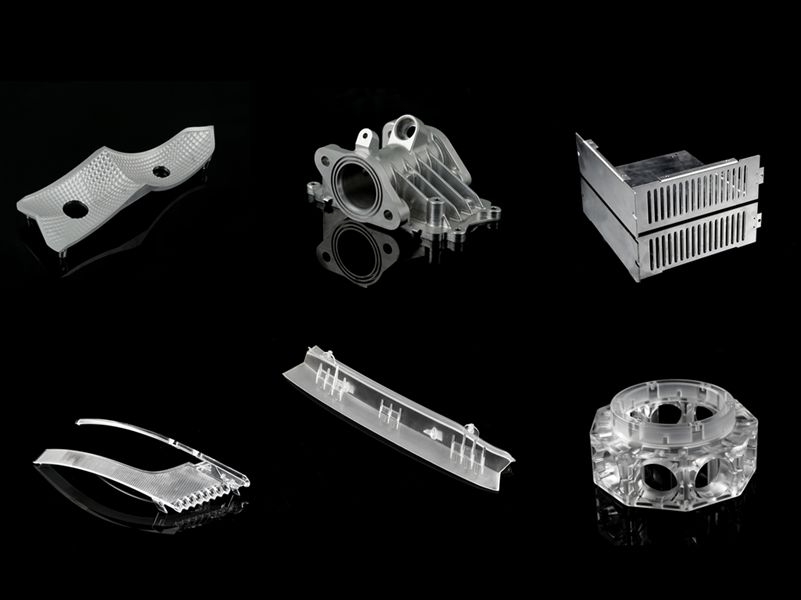

The advantage of the CNC prototype is that it can very accurately reflect the information expressed in the drawings, and the surface quality of the CNC prototype is high. Especially after surface spraying and silk screen printing, it is even more radiant than the products produced after the mold is opened. Therefore, CNC prototype manufacturing has increasingly become the mainstream of prototype manufacturing.

According to the materials used:

According to the materials used in production, prototypes can be divided into plastic prototypes, silicone prototypes, and metal prototypes:

(1) Plastic prototypes: The raw materials are plastic, mainly prototypes of some plastic products, such as TVs, monitors, telephones, etc.

(2) Silicone prototypes: The raw material is silica gel. They are mainly prototypes that display the design appearance of products, such as cars, mobile phones, toys, handicrafts, daily necessities, etc.

(3) Metal prototypes: The raw materials are aluminum-magnesium alloy and other metal materials, mainly prototypes of some high-end products, such as laptops, high-end radio players, MP3 players, CD players, etc.

Processing method:

CNC prototypes are divided into two types according to processing methods: laser rapid prototyping (SLA/SLS) and CNC processing, each of which has its own specialized processing materials.

1. Laser rapid prototyping (SLA/SLS)

Laser rapid prototyping is divided into SLA and SLS based on different raw materials.

SLA is a process that uses the principle of stereolithography, also known as selective curing of photosensitive resin. It is the earliest rapid prototyping technology. The process is: fill the resin tank with liquid photosensitive resin, which will quickly solidify under the irradiation of an ultraviolet laser beam. When the molding process begins, the liftable workbench is at a height of one cross-sectional layer thickness below the liquid surface. The focused laser beam scans along the liquid surface in accordance with the requirements of the cross-sectional profile under the control of the computer, so that the scanned area The resin is cured, thereby obtaining a resin sheet with the cross-sectional profile. Then, the workbench is lowered by the height of one layer of sheet, and the cured resin sheet is covered with a new layer of liquid resin for the second layer of laser scanning and curing. The newly cured layer is firmly bonded to the previous layer. Repeat this until the entire product is formed. Finally, cleaning, support removal, secondary curing and surface smoothing are performed.

Photosensitive resin selective curing rapid prototyping technology is suitable for making small and medium-sized workpieces, and can directly obtain resin or similar engineering plastic products. The prototype of SLA rapid prototyping has good surface quality, high system resolution and high molding accuracy.

The processing method of SLS is similar to SLA technology, but powder raw materials are used instead of liquid photopolymers, and the powder materials are acted on at a certain scanning speed and energy. During the forming process, laser parameters, powder characteristics and sintering atmosphere are important factors affecting the quality of sintering forming. SLS rapid prototyping can produce the hardest prototypes and can use a variety of raw materials, such as most engineering plastics, waxes, metals, ceramics, etc. The parts can be built at a high speed without the need for post-correction of parts and no need for design and structural support. .

2. CNC rapid prototyping

CNC is widely used in the mechanical processing industry and the technology is relatively mature. Used for prototype processing. The effect and accuracy are also very good. The first thing to consider is the prototype processing method.

Management style

If prototype companies want to become bigger and stronger, they must have good management methods: the implementation of ISO, a high-quality workforce, advanced processing and manufacturing equipment, and advanced management solutions, from customer management, business management, project management, and follow-up.

Comprehensive management such as order management, programming management, CNC management, tool management, Sla management, quality management, warehouse management, customer feedback management, financial management, etc., refined to every part and every processing tool path, the order follower can real-time Follow up on production progress.