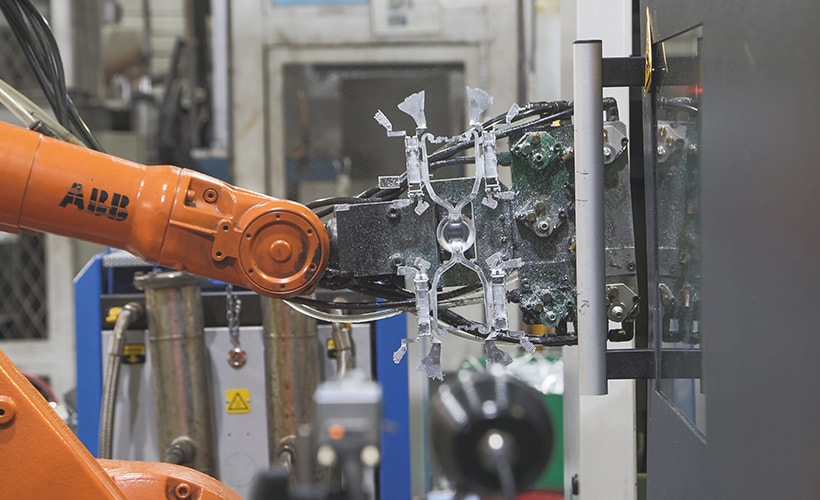

Die Casting .

Die casting is the process of shaping metal into a specific shape, known as casting.

Many different non-ferrous metals can be used in die-casting processes to achieve a large number of die-casting applications.

In fact, any metal part can be created using die casting technology, whether it is simple or complex. Metal components have extremely strong heat and corrosion resistance,

making them very suitable for applications in many industries, including automotive, aerospace, industrial, and energy industries.

Technical advantage

Rapid Model has a large plant and a professional R & D team, which can tailor-make products

and a complete set of processing and treatment solutions for you according to your company's specific situation.

Introduce professional production equipment and scientific management to ensure product quality,

product equipment, and a number of high-efficiency machinery, mainly producing and processing aluminum alloy pressure castings.

-

Technical Experience

Decades of industry experience, senior engineers. Combining advanced production equipment, complete production lines, and perfect technological processes, we can provide a complete one-stop solution for die-casting design and production.

1 -

Precision process

Sophisticated mold making and surface treatment technology to avoid 98% + solution defects before mold opening.

2

High-precision alloy die castings, error controllable, uniform density of finished products, no foaming, not easy to break and deform -

Quality Control

We have an experienced quality inspection team to inspect the quality of products and ensure that they are checked at every level. From production to shipment, we need to go through multiple full inspection processes to ensure zero errors.

3 -

Delivery capability

Our engineering design team participates in the customer's mold design and development throughout the process, assisting customers in quickly confirming and completing the design structure diagram, providing suggestions for optimizing product structure improvement, and effectively controlling time and capital costs.

4 -

Quality service

Professional service level team to create a perfect service system, one-to-one customer service, the whole process for the customer to think, thoughtful, customer satisfaction is the proof of our efforts have been rewarded.

5

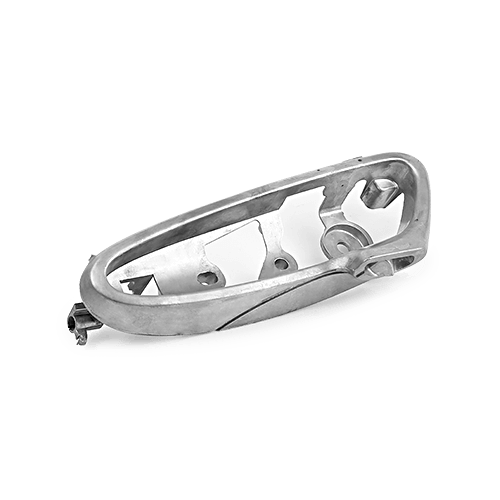

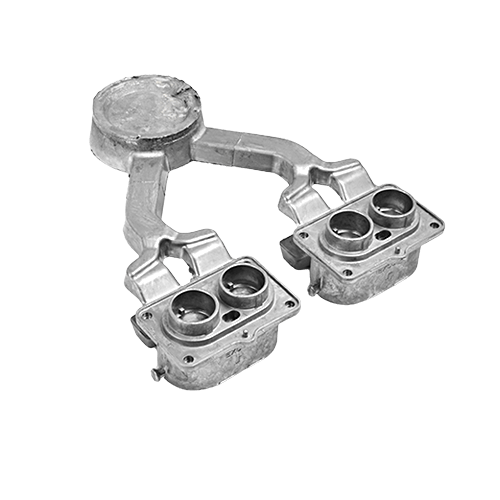

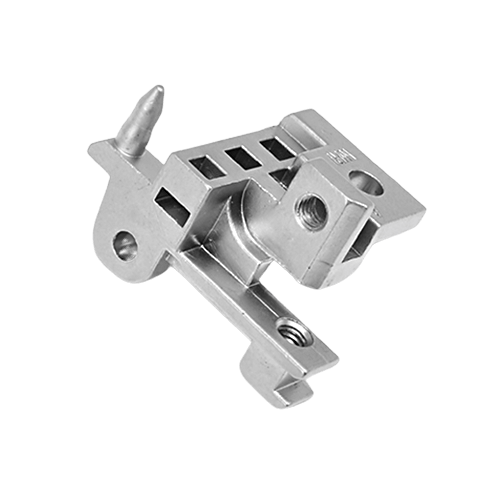

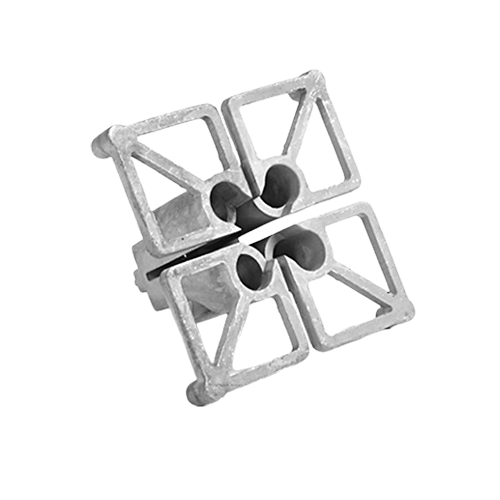

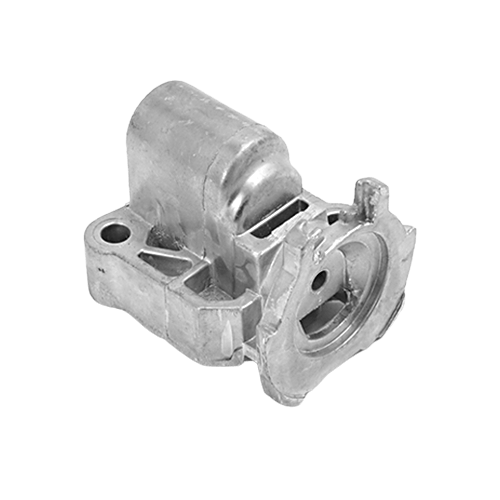

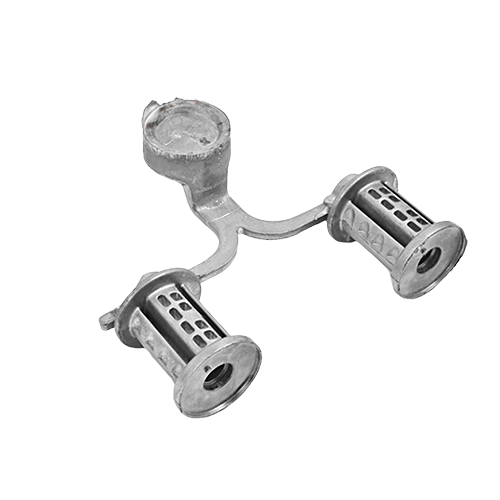

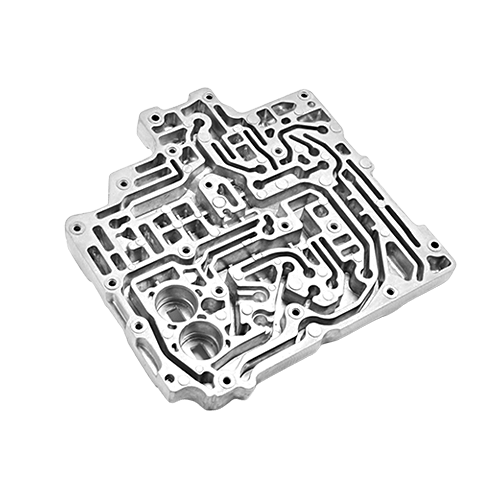

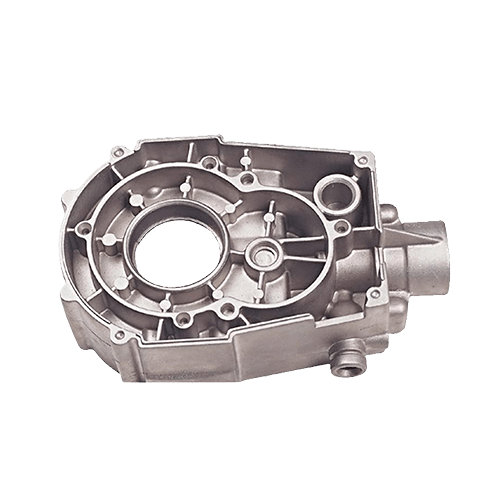

Die-casting case studies

Our engineering design team is fully involved in the customer's mold design and development,

assisting them in quickly confirming the completion of the design structure diagram, providing suggestions for optimizing product structure improvement,

and effectively controlling time and capital costs.