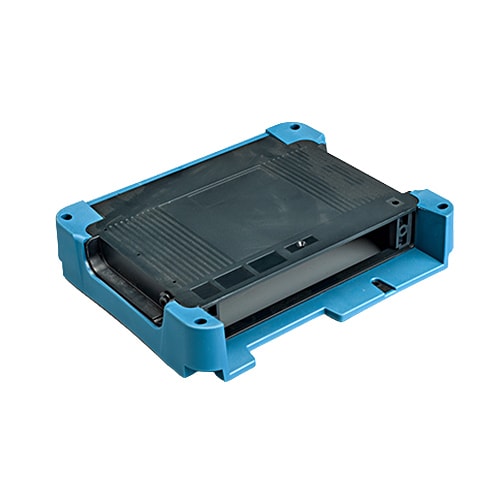

Mold design

We can provide professional design based on customer drawings, samples, and requirements, building upon traditional mold design. And fully utilize digital and information technology to improve the quality of mold design and shorten the mold design cycle.